Why Choose

SoftWash Systems Equipment?

At SoftWash Systems, we understand that there are many places to purchase your soft washing equipment. SoftWash Systems is well known in the industry as the innovator of new products and implementing them into our equipment and business practice, this allows for soft washing organizations to stay at the top of their game. Additionally, SoftWash Systems equipment is custom “made-to-order”, and is specifically designed to fit your budget and your needs, and have the ability to add, take away, or replace pieces as your company and needs grow.

SoftWash Systems equipment is all built by a manufacturing company located directly next door to SoftWash Systems offices and warehouses. Because of this SoftWash Systems has the unique ability of direct, face-to-face communication between companies, in order to give each skid the attention it deserves. This partnership also means that there are multiple minds working on each skid, and that each piece of equipment that leaves the warehouse goes through a rigorous procedure for quality assurance.

SoftWash Systems equipment stands out from the others:

Extremely quiet design!

Long gone are the days of a quiet neighborhood being ruined by loud machines. Our equipment is quieter than most household vacuum cleaners.

It’s battery operated!

Forget about power cords or refilling gas. Our designs use rechargeable batteries to keep you on the move. Reducing Fossil fuel emissions is one of our Good Stewards initiatives.

Park in a garage? No problem!

Our ladder racks are easily removable for when you need your truck to just be a truck. Forklift the skid out in winter, or at the end of your season easily.

Decide your specialty!

Our easily customizable skids allow you to design the perfect equipment for exactly your needs.

No math! Easy training.

Our equipment makes your life easier. When you purchase SoftWash Systems equipment, you are purchasing equipment that measures for you so that you can focus on the cleaning! No more “one batching”.

Sticking to a budget?

Because our skids are customizable, we are able to help you find a price that works for you. As your company and profits grow, our skids are easy to reconfigure and add to them! We help your skid grow with you!

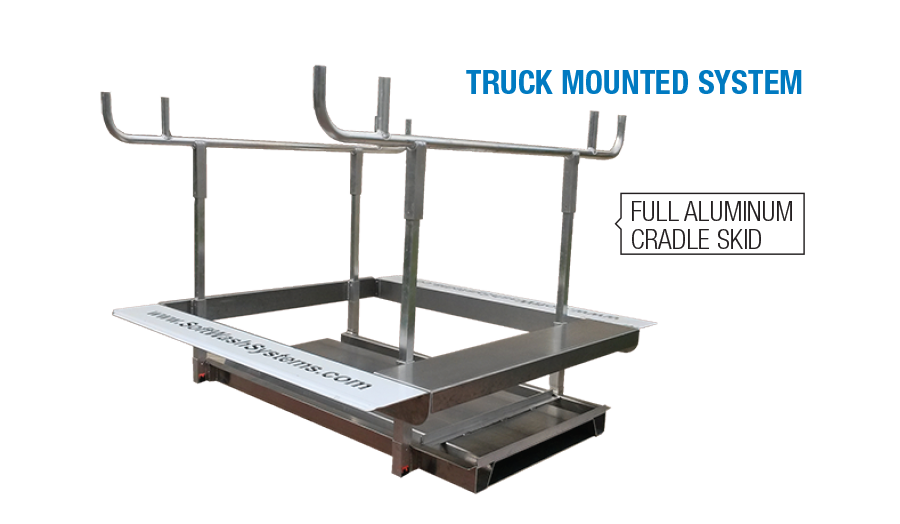

The Foundational Design

Each SoftWash Systems skid, although completely customizable, has the same base foundation: our proprietary cradle skid. Each full skid that leaves our building features a Lower Skid Unit. Simply put, this means that the cradle skid is able to be mounted easily into a pick-up truck, trailer, van or box truck. In addition to a spray-in bed liner this design is made to keep water, overspray, and chemicals from collecting in the truck bed and seeping into valuable vehicle systems and parts underneath. Easy clean up at the end of day – simply neutralize, rinse, and you’re done!

NEED MORE INFORMATION?

A customer service agent can help you with all of your questions!

GENERATION III

CRADLE SKID

Our SoftWash Systems Full Aluminum Cradle Skid has been through multiple generational changes since 1998. This design features a universal fit that allows the skid to be mounted into any mid-size or full-size truck bed, with the minimum requirement of six feet (6’ US) in length. The bed rails telescope vertically, allowing for various truck bed depths and widths. The right and left bed rails have also been extended to 10” so that reels can be mounted on the sides or rear of the system. This allows the user to have a 270 degree (three-sided) mounting area for reels.

Our new modular line-up includes basic elements to build upon our Cradle Skid format. These elements are our Tank Modules.

“Tank Modules” are self-contained machines built on top of our 50-gallon poly tanks and our Aluminum Graduated Tank Straps. These are standalone pieces of equipment that need little or no mechanical expertise to install. This allows soft washing professionals to easily upgrade or even change the configuration of their Cradle Skid System by only removing four bolts. On every module, all the electrical, plumbing and controls are mounted atop the Graduated Tank Strap for a true plug-and-play installation. Each tank module has a specific purpose for your soft wash skid.

Tank modules are customizable on this skid as well. This cradle skid can fit up to (4) of our 50-gallon tank modules, or (2) 100-gallon tank modules, depending on needs. Mix and match 50-gallon or 100-gallon tanks as you wish! SoftWash Systems knows that each company is unique, which is why this design allows for customization of the skid for multiple cleaning techniques, including pure water window cleaning and pressure/power washing in addition to soft washing.

Our Generation II Cradle Skid also includes a built-in, removable ladder rack. With this new design, we wanted to think about all types of companies, which is why our Gen III skid has the ability for easy removal of the ladder rack in order to park your truck in a garage. We understand that some of our companies are working out of deed-restricted communities, and want to make sure that this skid meets their needs as well. Generation III cradle skid is also available without a ladder rack, so that you may use your preferred ladder rack, or even house the system under a commercial truck cap.

GLOBAL SKID DESIGN:

GENERATION III FOR THE WORLD

SoftWash Systems has In-Network companies currently in 9 different countries. We strive to continually keep these businesses at the same level as our In-Network Companies here in America. From this desire, the World System Integration Generation II Format was born. The tank modules in this skid can be switched to either side of the cradle skid to accommodate non-US vehicles. These changes mean that our skids look different in other parts of the world, but users can be confident in their SoftWash Systems equipment being adaptable to their vehicular differences. For example, vans are extremely common for the large majority of the worlds’ soft washing markets. With this understanding, it is incredibly important that our equipment is still able to function at the designed ability in every country.

The entire cradle skid system has been configured into easily assembled components, which can then be purchased separately as you move your SoftWash Systems from a trailer, to a van, and eventually into a truck bed.

These Global Skids also include the Lower Skid Unite (LSU) as described above. In this case, the LSU can be used alone to mount any of our World System Modules, allowing access from both the curbside left (EU) or curbside right (US). This skid also comes in 4 sizes – up to XL. The XL is 6’ in length, and 40” wide, with built-in forklift pockets. This XL LSU can be easily mounted into a van, allowing up to four mounted tank modules. Each one of the four modules would have a square modular 50- US Gallon (189-liter), or a 100-US gallon (378-liter) poly tank, giving the user water and a chemical capacity total of 200-US gallon (758-liter).

GROWING YOUR EQUIPMENT AS YOU GROW YOUR COMPANY IS EASY WITH THIS SYSTEM!

BLEND 2X AND 3X

TECHNOLOGY

The Blend 3X has two different soap sources – the first a dedicated soap saddle tank, and the second a soap “stinger”. A soap stinger is a suction device we make that connects easily to the Blend head, and will pull from any soap source you want. (e.g. a 5-gallon bucket, or a gallon of chemical you have on the truck) There is a bleach metering valve that will allow you to set the desired percentage of chemicals coming out of the wand. The Blend head will do all the mixing for you, so you can focus your attention on the property you are cleaning. Let the machine do all the work for you!

NOTE: Blend Technology from SoftWash Systems should not be confused with downstream injection. Commonly referred to as “down streaming” by pressure/power washers, this process is the use of a venturi-style injector that draws a small amount of chemical from a bucket into the power/pressure washing line to wash exteriors. Though more chemical can be drawn and applied by using a larger orifice tip in the pressure washing gun, this downstream injector becomes less and less effective and has less and less of a draw the further one moves from the physical pressure washer, or the higher up wash. Additionally, many of these injectors only operate at a 10/1 ratio which is not strong enough to soft wash with.

ON A BUDGET?

Start small with the Blend 2X or 3X 50-gallon, and add onto your system as the profits from your soft washing business can pay for upgraded equipment.

CONFUSED?

LET ME TELL YOU HOW EASY IT IS TO USE IN 4 QUICK STEPS…

Step 1

Turn the Bleach Metering valve to your desired percentage.

Step 2

Turn one Soap Metering valve to your desired percentage.

Step 3

Set the bottom valves to this pattern from left to right (Horizontal, Vertical, Vertical Horizontal).

Step 4

Turn on Power, and you’re ready to spray!

THE GRADUATED TANK STRAP

Another SoftWash Systems innovation is the Aluminum Graduated Tank Strap. This proprietary technology allows us to secure our 50 and 100-gallon tanks to any of our LSU’s, and securely mount equipment atop of the tanks, saving valuable space, and building upwards rather than outwards. Again, these modules can be mounted either curbside right (US) or curbside left (EU). Up to four (4) tank modules can be mounted on any one system in various configurations allowing for optimal use. Modules can be added to your SoftWash Systems Cradle Skid that allows for more efficient and space-saving use of basic operations alongside soft washing, all neatly and safely within a single truck cargo bed.

Blend 6X

Technology

BLEND 6X BASE MODEL

BLEND 6X – FULL CRADLE SKID MODEL

BLEND 6X – FULL CRADLE SKID MODEL WITH POWER WASH

BLEND 6X – FULL CRADLE SKID MODEL WITH PURE WATER

BLEND 6X – FULL CRADLE SKID MODEL WITH PURE WATER & POWER WASH

A Legacy

To Uphold

SoftWash Systems created the soft washing industry. Because of this, we believe we have a responsibility to lead, innovate, and provide the tools for our in-network companies to succeed and grow. Our legacy fulfilled would be to look back and see that our equipment, chemicals, education, and support provided the catalyst necessary for small businesses and entrepreneurs to support their families and create jobs. We at SoftWash Systems know that leadership through innovation creates opportunity and fosters our legacy.